Cylinder Stress Formula for Boiler Design: A Comprehensive Guide

Boilers, critical components in power generation and various industrial processes, rely on the safe and efficient containment of high-pressure fluids. A thorough understanding of the stresses developed within the cylindrical shell of a boiler is paramount for ensuring its structural integrity and preventing catastrophic failures. This article delves into the cylinder stress formula, its derivation, applications in boiler design, and important considerations for accurate stress analysis. We'll explore the different types of stresses experienced by cylindrical pressure vessels, provide practical examples, and address common questions related to stress calculations.

Understanding Stresses in Cylindrical Pressure Vessels

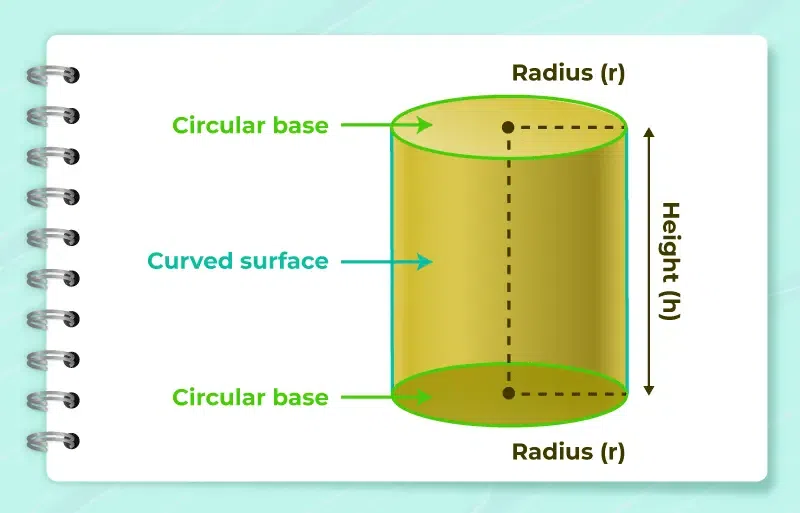

Cylindrical pressure vessels, including boilers, are subjected to various stresses when subjected to internal pressure. The primary stresses are hoop stress (circumferential stress) and longitudinal stress (axial stress). These stresses arise from the force exerted by the internal pressure acting on the cylinder walls. Understanding these stresses is crucial for selecting appropriate materials and determining the required wall thickness of the boiler.

Hoop Stress (Circumferential Stress)

Hoop stress, denoted as σh, acts circumferentially around the cylinder, tending to expand its radius. It is the dominant stress in thin-walled cylinders.

Formula Derivation: Consider a thin-walled cylinder with internal pressurep, inner radiusr, and wall thicknesst. If we isolate a longitudinal section of the cylinder of length L, the force due to the internal pressure acting on this section isp(2r L). This force is resisted by the tensile stress acting on the two cross-sectional areas of the cylinder wall:2t Lσh. Equating these forces, we get:p(2r L) = 2t Lσh

Solving for σh, we obtain the hoop stress formula:σh = (pr) / t

This formula is applicable for thin-walled cylinders, where the ratio of the radius to the thickness (r/t) is greater than 10.

Longitudinal Stress (Axial Stress)

Longitudinal stress, denoted as σl, acts along the longitudinal axis of the cylinder, tending to elongate it.

Formula Derivation: Consider the same thin-walled cylinder. The force due to the internal pressure acting on the end cap of the cylinder ispπr2. This force is resisted by the tensile stress acting on the cross-sectional area of the cylinder wall: 2πrtσl. Equating these forces, we get:pπr2 = 2πrtσl

Solving for σl, we obtain the longitudinal stress formula:σl = (pr) / (2t)

Notice that the longitudinal stress is half the hoop stress.

Radial Stress

Radial stress, denoted as σr, acts in the radial direction, from the inside to the outside of the cylinder wall. Its magnitude varies from–pat the inner surface to 0 at the outer surface. For thin-walled cylinders, radial stress is usually negligible compared to hoop and longitudinal stresses. However, in thick-walled cylinders, radial stress becomes significant and needs to be considered.

Combined Stress State

The cylinder wall experiences a triaxial stress state: hoop stress, longitudinal stress, and radial stress. While hoop and longitudinal stresses are tensile (positive), radial stress is compressive (negative). For thin-walled cylinders, the radial stress is often ignored, and the analysis simplifies to a biaxial stress state.

Application of Cylinder Stress Formulas in Boiler Design

The cylinder stress formulas are fundamental to boiler design. Engineers use these formulas to determine the minimum required wall thickness for a given operating pressure and material strength. The design process typically involves the following steps:

1.Determine the design pressure (p): This is the maximum pressure the boiler is expected to operate at, plus a safety margin.

2.Select the material: The material selection depends on the operating temperature, pressure, and corrosive environment. Common boiler materials include carbon steel and alloy steel. The material’s allowable stress (S) at the operating temperature must be known. This allowable stress incorporates a safety factor to account for uncertainties in material properties, manufacturing tolerances, and operating conditions.

3.Determine the inner radius (r): This is based on the desired boiler capacity and geometry.

4.Calculate the minimum required wall thickness (t) based on hoop stress: Using the hoop stress formula (σh = (pr) / t), solve fort*:t = (pr) / S

Where S is the allowable stress for the chosen material.

5.Calculate the minimum required wall thickness (t) based on longitudinal stress: Using the longitudinal stress formula (σl = (pr) / (2t)), solve fort*:t = (pr) / (2S)

6.Choose the larger of the two calculated thicknesses: This ensures that the boiler is safe against both hoop and longitudinal stresses. In most cases, the thickness calculated based on hoop stress will be larger.

7.Consider additional factors: The calculated thickness is a minimum requirement. Additional factors, such as corrosion allowance, manufacturing tolerances, and the presence of stress concentrations (e.g., near nozzles or welds), must be considered to ensure the boiler's long-term reliability. Codes and standards, such as the ASME Boiler and Pressure Vessel Code, provide detailed guidelines for these considerations.

Worked Examples

Here are two examples demonstrating the application of cylinder stress formulas in boiler design.

Example 1: Thin-Walled Cylinder

A cylindrical boiler with an internal diameter of 2 meters operates at a pressure of 10 MPa. The allowable stress for the boiler material is 100 MPa. Calculate the minimum required wall thickness.

1.Design Pressure (p): 10 MPa

2.Inner Radius (r): 1 meter (2 meters / 2)

3.Allowable Stress (S): 100 MPa

Thickness based on hoop stress:

t = (pr) / S = (10 MPa 1 m) / 100 MPa = 0.1 meters = 100 mm

Thickness based on longitudinal stress:

t = (pr) / (2S) = (10 MPa 1 m) / (2 100 MPa) = 0.05 meters = 50 mm

Since the thickness calculated based on hoop stress (100 mm) is greater than the thickness calculated based on longitudinal stress (50 mm), the minimum required wall thickness is 100 mm. Additional corrosion allowance and manufacturing tolerances must be added to this value in a real-world design.

Example 2: Accounting for Corrosion Allowance

A cylindrical pressure vessel with an internal diameter of 1.5 meters operates at a pressure of 5 MPa. The allowable stress for the material is 80 MPa, and a corrosion allowance of 3 mm is required. Calculate the minimum required wall thickness.

1.Design Pressure (p): 5 MPa

2.Inner Radius (r):

0.75 meters (1.5 meters / 2)

3.Allowable Stress (S): 80 MPa

4.Corrosion Allowance (C): 3 mm =

0.003 meters

Thickness based on hoop stress (without corrosion allowance):

t = (pr) / S = (5 MPa 0.75 m) / 80 MPa =

0.046875 meters =

46.875 mm

Thickness based on longitudinal stress (without corrosion allowance):

t = (pr) / (2S) = (5 MPa 0.75 m) / (2 80 MPa) =

0.0234375 meters =

23.4375 mm

Minimum thickness before corrosion allowance: 46.875 mm

Total thickness (including corrosion allowance):

ttotal = 46.875 mm + 3 mm =

49.875 mm

Therefore, the minimum required wall thickness, including the corrosion allowance, is approximately 49.875 mm. Again, this is a minimum value, and further considerations from design codes will likely increase this value.

Considerations for Thick-Walled Cylinders

The formulas presented above are accurate forthin-walled cylinders, where the ratio of radius to thickness (r/t) is greater than 10. Forthick-walled cylinders(r/t ≤ 10), the stress distribution is more complex, and the hoop stress is no longer uniform across the wall thickness. In thick-walled cylinders, the hoop stress is highest at the inner surface and decreases towards the outer surface. Lame's equations are used to calculate the stresses in thick-walled cylinders:

σh = p (ri2 + ro2) / (ro2 - ri2) (at the inner surface)

Where:

ri is the inner radius

ro is the outer radius

p is the internal pressure

The radial stress at any point within the cylinder wall is given by:

σr = p (ri2) (1 - ro2/r2) / (ro2 - ri2)

Whereris the radius at the point of interest.

Common Pitfalls and Misconceptions

Applying thin-walled cylinder formulas to thick-walled cylinders: This can lead to significant errors in stress calculations and potentially unsafe designs. Always check the r/t ratio to determine whether thin-walled or thick-walled cylinder formulas are appropriate. Ignoring stress concentrations: Stress concentrations occur at geometric discontinuities, such as holes, nozzles, and welds. These areas experience significantly higher stresses than the nominal stress calculated using the cylinder stress formulas. Finite element analysis (FEA) or experimental stress analysis techniques should be used to evaluate stress concentrations. Neglecting corrosion allowance: Corrosion can significantly reduce the wall thickness of a boiler over time, leading to increased stress levels and potential failure. Always include an appropriate corrosion allowance in the design. Using incorrect units: Ensure that all units are consistent (e.g., MPa for pressure and stress, meters for radius and thickness) to avoid errors in calculations.

People Also Ask

How do you calculate hoop stress in thin-walled cylinders?

Hoop stress (σh) in a thin-walled cylinder is calculated using the formula: σh = (pr) / t, wherepis the internal pressure,ris the inner radius, andtis the wall thickness. This formula assumes a uniform stress distribution across the wall thickness and is valid when the ratio of radius to thickness (r/t) is greater than 10.

What is the difference between true stress and engineering stress?

Engineering stress is calculated by dividing the applied force by the original cross-sectional area of the material. True stress, on the other hand, is calculated by dividing the applied force by theinstantaneouscross-sectional area of the material, which changes as the material deforms. True stress provides a more accurate representation of the stress state in materials undergoing significant plastic deformation. For boiler design involving elastic stresses, engineering stress is typically sufficient.

When should principal stress formulas be applied in design?

Principal stress formulas are applied when analyzing components subjected to combined stresses, meaning stresses acting in multiple directions. These formulas determine the maximum and minimum normal stresses (principal stresses) and the maximum shear stress at a point. They are crucial for determining the failure criterion of a material under complex loading conditions. In boiler design, principal stresses are important when analyzing areas with stress concentrations or complex geometries, such as nozzle connections. Mohr's Circle can be used as a visual aid for determining principal stresses.

Conclusion

The cylinder stress formula is a cornerstone of boiler design, providing a fundamental understanding of the stresses developed within the cylindrical shell. By accurately calculating hoop and longitudinal stresses and considering factors such as corrosion allowance, stress concentrations, and the applicability of thin-walled versus thick-walled cylinder assumptions, engineers can ensure the structural integrity and safe operation of boilers. Adherence to established codes and standards, such as the ASME Boiler and Pressure Vessel Code, is essential for designing reliable and safe pressure vessels. Further investigation using FEA for complex geometries is also crucial for ensuring safety.