Thermal Stress Formula for Temperature Gradients: A Comprehensive Guide

Thermal stress, a critical consideration in mechanical engineering design, arises from the expansion or contraction of materials due to temperature changes. When a material is unrestrained, it expands or contracts freely without inducing stress. However, if this expansion or contraction is constrained, internal stresses develop. This article delves into the thermal stress formula specifically for scenarios involving temperature gradients, where the temperature varies across the material's geometry. We'll explore the underlying principles, relevant equations, and practical examples, ensuring a clear understanding for engineering students, practicing engineers, and researchers.

Thermal stresses induced by temperature gradients can lead to significant structural issues, including yielding, cracking, and even failure. Understanding and mitigating these stresses is crucial for ensuring the safety and reliability of engineered components and systems.

Understanding Thermal Stress

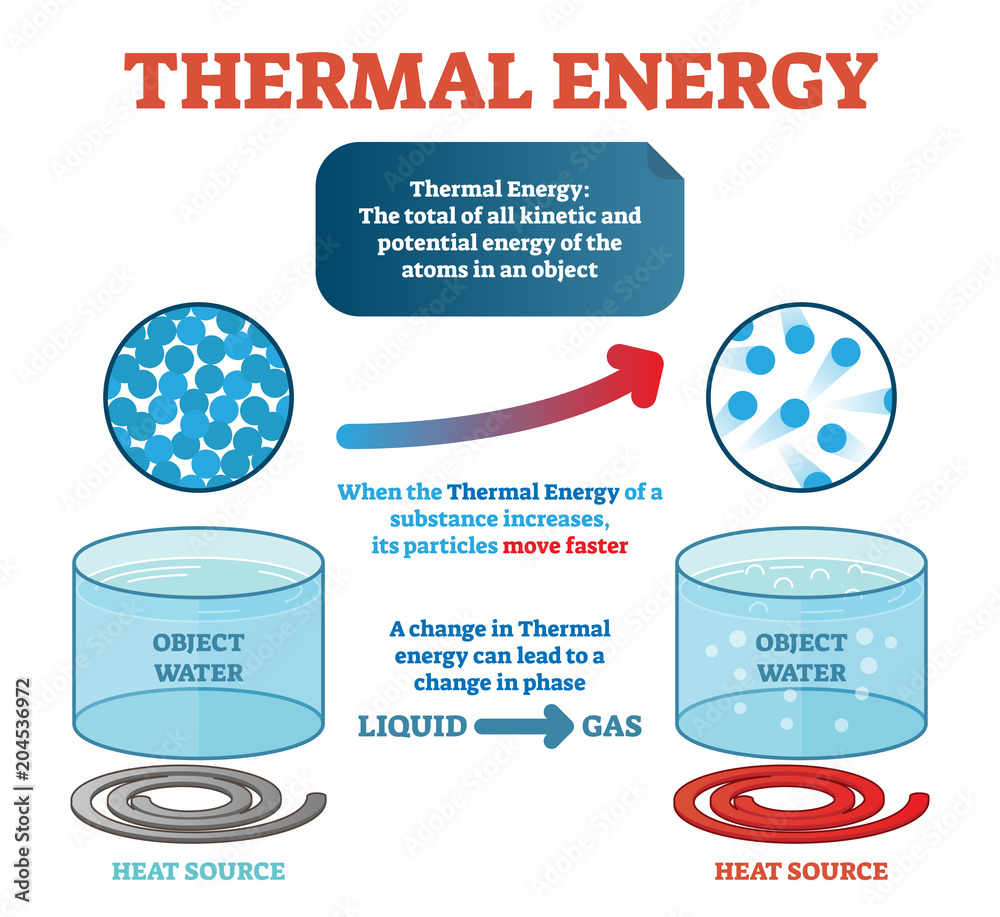

Thermal stress, denoted often by the symbol σth, is the stress induced within a material due to changes in temperature. This phenomenon arises because materials expand when heated and contract when cooled. The amount of expansion or contraction is directly proportional to the temperature change and the material's coefficient of thermal expansion.

If a material is free to expand or contract, no stress is generated. However, if the material is constrained, either externally or internally due to temperature gradients, internal stresses will develop. These stresses can be tensile (pulling) or compressive (pushing), depending on the nature of the constraint and the temperature distribution.

Basic Thermal Stress Formula (Uniform Temperature)

Before delving into temperature gradients, let's review the fundamental thermal stress formula for a uniform temperature change in a constrained member:

σth = -EαΔT

Where: σth is the thermal stress (Pa or psi)

E is the Young's modulus of the material (Pa or psi) – a measure of its stiffness. α is the coefficient of thermal expansion of the material (1/°C or 1/°F) – how much the material expands or contracts per degree change in temperature. ΔT is the change in temperature (°C or °F) – the difference between the final and initial temperatures.

The negative sign indicates that an increase in temperature (positive ΔT) in a constrained member leads to compressive stress, while a decrease in temperature (negative ΔT) leads to tensile stress.

Thermal Stress Due to Temperature Gradients

The situation becomes more complex when a temperature gradient exists within the material. A temperature gradient means that the temperature is not uniform but varies across the material's cross-section or length. This non-uniform temperature distribution leads to differential expansion and contraction, causing internal stresses even if the overall structure is free to expand. These stresses are significantly harder to calculate and require integrating across the entire section.

Deriving the Thermal Stress Formula for Temperature Gradients

Consider a long, slender beam subjected to a temperature gradient across its height, h. Let's assume the temperature varies linearly from T1 at the top surface to T2 at the bottom surface.

1.Strain due to Temperature Gradient: The thermal strain at any point 'y' from the neutral axis is given by:

ε(y) = αT(y)

where T(y) is the temperature at position 'y'. If the temperature varies linearly:

T(y) = T1 + (T2 - T1) (y + h/2) / h

2.Stress due to Thermal Strain: The stress at any point 'y' is related to the strain by Hooke's Law:

σ(y) = Eε(y) = EαT(y) = Eα [T1 + (T2 - T1) (y + h/2) / h]

3.Equilibrium Conditions: For the beam to be in equilibrium, the resultant force and moment due to the thermal stresses must be zero. This gives us two conditions: Resultant Force = 0:∫ σ(y) d A = 0

Resultant Moment = 0: ∫ σ(y) y d A = 0

4.Solving for Neutral Axis and Stress Distribution: These equilibrium conditions allow us to determine the location of the neutral axis and the stress distribution across the beam's height. Assuming a rectangular cross-section of width 'b', the integrals become: ∫ Eα [T1 + (T2 - T1) (y + h/2) / h] b dy = 0 (integrated from -h/2 to h/2)

∫ Eα [T1 + (T2 - T1) (y + h/2) / h] y b dy = 0 (integrated from -h/2 to h/2)

Solving these integrals (which involves calculus) leads to the following expressions for the stresses at the top and bottom surfaces of the beam:

σtop = Eα (T1 - Tavg) - (Eα(T2 - T1)h)/(2I)*y

σbottom = Eα (T2 - Tavg) - (Eα(T2 - T1)h)/(2I)y

Where Tavg is the average temperature, (T1+T2)/2, and I is the area moment of inertia of the beam's cross-section, bh3/12. The last term in each equation represents bending stress.

Simplified Thermal Stress Formula for Linear Temperature Gradient

For a linear temperature gradient and a rectangular cross section, we can simplify the above equations to a more usable form:

σtop = Eα/2 (T1 - T2)

σbottom = Eα/2 (T2 - T1)

This shows that the thermal stress is directly proportional to the temperature difference and the material properties (E and α).

People Also Ask

How does geometry affect thermal stress distribution?

The geometry of a component significantly influences the thermal stress distribution. Complex shapes with sharp corners or abrupt changes in cross-section tend to concentrate thermal stresses. This is because these geometric features restrict the free expansion or contraction of the material, leading to higher stress levels. Therefore, designers often try to avoid sharp corners and use fillets (rounded corners) to distribute stresses more evenly. In more complex shapes, finite element analysis is used.

What materials are more susceptible to thermal stress failures?

Materials with high coefficients of thermal expansion and high Young's moduli are more susceptible to thermal stress failures. A high coefficient of thermal expansion means that the material expands or contracts significantly with temperature changes, leading to larger thermal strains. A high Young's modulus means that the material is stiff and requires a large force to deform, which translates to higher stresses for a given strain. Brittle materials are particularly susceptible to thermal stress failures, as they have low tensile strength and cannot withstand significant tensile stresses without cracking.

How do you calculate hoop stress in thin-walled cylinders under thermal gradients?

Calculating hoop stress in thin-walled cylinders subjected to thermal gradients involves similar principles to the beam example. However, the geometry is different, and the stress state is two-dimensional. The temperature gradient typically varies through the thickness of the cylinder wall. The analysis involves integrating the thermal strain across the wall thickness and considering the equilibrium of forces and moments in the circumferential (hoop) direction. Finite element analysis (FEA) is frequently employed for accurate stress predictions in complex cylinder geometries and temperature distributions. The general approach involves finding the average thermal strain, determining the hoop strain based on constraints (e.g., fixed ends), and then calculating the hoop stress using the material's properties.

Practical Examples

Let's explore two practical examples to illustrate the application of the thermal stress formula for temperature gradients.

Example 1: Bimetallic Strip

A bimetallic strip is made of two different metals bonded together. Let's say we have a strip consisting of steel and aluminum, each with a thickness of 1mm, bonded together along their length. The steel has a coefficient of thermal expansion of 12 x 10-6 /°C and a Young's modulus of 200 GPa. The aluminum has a coefficient of thermal expansion of 23 x 10-6 /°C and a Young's modulus of 70 GPa. The strip is initially at 20°C and then heated to 100°C.

Due to the difference in thermal expansion coefficients, the aluminum will try to expand more than the steel. However, since they are bonded together, this differential expansion will induce bending stresses in the strip, causing it to curve.

To estimate the stresses, we can use a simplified approach. First, calculate the free thermal strain for each metal: εsteel = αsteel ΔT = (12 x 10-6 /°C) (100°C - 20°C) = 9.6 x 10-4 εaluminum = αaluminum ΔT = (23 x 10-6 /°C) (100°C - 20°C) =

1.84 x 10-3

The difference in strain is:

Δε = εaluminum - εsteel = 1.84 x 10-3 -

9.6 x 10-4 =

8.8 x 10-4

This strain difference causes bending. While a precise stress calculation requires more advanced analysis, we can approximate the stress in each material. Because they are bonded, the internal force has to be balanced. Therefore:

σaluminum A = σsteel A

Where A is the area.

Because stress and strain are linearly related we can also say Ealuminum εaluminum = Esteel εsteel.

εsteel + Δε = εaluminum

Ealuminum(εsteel + Δε) = Esteel εsteel

EaluminumΔε = (Esteel - Ealuminum)εsteel

Solving for the change in strain:

εsteel = (EaluminumΔε)/(Esteel - Ealuminum) = (708.810-4)/(200-70) =

4.75 10-4

Knowing this strain value, we can find the final strain values and stress values:

εaluminum,final = 4.7510-4 +

8.8 10-4 =

1.35510-3

εsteel,final = 4.75 10-4

σaluminum, final = 1.35510-3 70109 =

94.85 MPa (Compression)

σsteel, final = 4.75 10-4 200109 = 95 MPa (Tension)

This simplified calculation provides an order-of-magnitude estimate of the stresses. Note that the actual stress distribution will be more complex due to the bending and shear stresses at the interface.

Example 2: Heated Steel Plate

Consider a large steel plate with a thickness of 25mm. One side of the plate is maintained at a temperature of 200°C, while the other side is maintained at 50°C. The steel has a coefficient of thermal expansion of 12 x 10-6 /°C and a Young's modulus of 200 GPa. We want to estimate the thermal stresses in the plate.

Assuming a linear temperature gradient through the thickness, the temperature difference is ΔT = 200°C - 50°C = 150°C. We can use the simplified thermal stress formula for a linear temperature gradient:

σtop = Eα/2 (T1 - T2) = (200 x 109 Pa) (12 x 10-6 /°C) / 2 (200°C - 50°C) = 180 MPa (Compression)

σbottom = Eα/2 (T2 - T1) = (200 x 109 Pa) (12 x 10-6 /°C) / 2 (50°C - 200°C) = -180 MPa (Tension)

This indicates a compressive stress of 180 MPa on the hotter side and a tensile stress of 180 MPa on the cooler side. These stresses can be significant and may lead to yielding or cracking, especially if the steel has pre-existing defects or stress concentrations. In cases like this, designers must determine whether the stress levels are safe.

Common Pitfalls and Misconceptions

Assuming Uniform Temperature: A common mistake is to assume a uniform temperature distribution when a gradient exists. This can lead to significant underestimation of thermal stresses. Ignoring Constraints: Neglecting the constraints on a material's expansion or contraction is another frequent error. If a component is fully constrained, the thermal stresses will be much higher than if it is free to expand. Using Linear Elasticity Assumptions for Large Temperature Changes: At very high temperatures, the material properties (E and α) may change significantly, and the linear elasticity assumptions may no longer be valid. Overlooking Stress Concentrations: Sharp corners and other geometric features can concentrate thermal stresses, leading to localized failure.

Conclusion

Understanding and accurately calculating thermal stresses due to temperature gradients is crucial for the design of safe and reliable engineering components and structures. This article has provided a comprehensive guide to the relevant formulas, concepts, and practical examples. Remember to consider the material properties, geometry, and boundary conditions carefully when analyzing thermal stress problems. For complex geometries and temperature distributions, finite element analysis (FEA) offers a powerful tool for accurate stress prediction. By avoiding common pitfalls and misconceptions, engineers can effectively mitigate thermal stress-related failures and ensure the integrity of their designs.