The application of the maximum stress formula is paramount in ensuring the structural integrity and safety of various constructions, ranging from towering skyscrapers to intricate machine components. Understanding how to calculate and interpret maximum stress allows engineers to predict potential failure points and design structures that can withstand anticipated loads and environmental conditions. This article delves into the theoretical underpinnings of maximum stress, explores its practical application in construction, and provides examples to illustrate its importance in engineering design.

Understanding the Maximum Stress Formula

The concept of maximum stress revolves around determining the highest stress value within a material subjected to external forces. Stress, generally denoted by the Greek letter sigma (σ), is defined as the force (F) acting per unit area (A):

σ = F/A

This basic formula represents normal stress, where the force is perpendicular to the area. However, in real-world applications, stress can be more complex and involve multiple components acting in different directions. The maximum stress, also known as the principal stress, represents the largest normal stress experienced by a material at a particular point, regardless of the orientation of the plane on which it acts.

To determine the maximum stress, one must often consider the combined effects of normal stresses (σx, σy, σz) and shear stresses (τxy, τyz, τxz). This is typically done using stress transformation equations or Mohr's circle, a graphical representation of stress at a point.

For a two-dimensional stress state (plane stress), the principal stresses, σ1 and σ2, are calculated as follows:

σ1,2 = (σx + σy)/2 ± √[((σx - σy)/2)^2 + τxy^2]

Where: σx and σy are the normal stresses in the x and y directions, respectively. τxy is the shear stress in the xy plane.

The maximum shear stress (τmax) is then:

τmax = (σ1 - σ2)/2

It's crucial to understand that the maximum stress is not simply the largest applied stress component. It represents the most critical stress state a material experiences, accounting for combined loading scenarios.

Applying Maximum Stress in Construction: Real-World Examples

The maximum stress formula finds applications in diverse fields within construction and mechanical engineering. Here are some prominent examples:

Structural Steel Design

In structural steel design, engineers use the maximum stress criteria to ensure that beams, columns, and connections can withstand the intended loads without yielding or fracturing. Steel structures are subjected to various loads, including dead loads (weight of the structure itself), live loads (occupancy loads), wind loads, and seismic loads.

Example: Consider a steel beam supporting a floor in a building. The beam is subjected to bending moments and shear forces. The bending moment creates tensile and compressive stresses in the beam, while the shear force induces shear stresses. Using the bending stress formula (σ = My/I, where M is the bending moment, y is the distance from the neutral axis, and I is the moment of inertia) and shear stress formula (τ = VQ/Ib, where V is the shear force, Q is the first moment of area, b is the width, and I is the moment of inertia), engineers can determine the distribution of normal and shear stresses within the beam. Then, by applying the maximum stress criteria (often utilizing the von Mises yield criterion, discussed later), they can check if the calculated maximum stress exceeds the allowable stress for the steel grade being used. If the maximum stress is too high, the beam's dimensions must be increased, or a stronger steel grade must be selected.

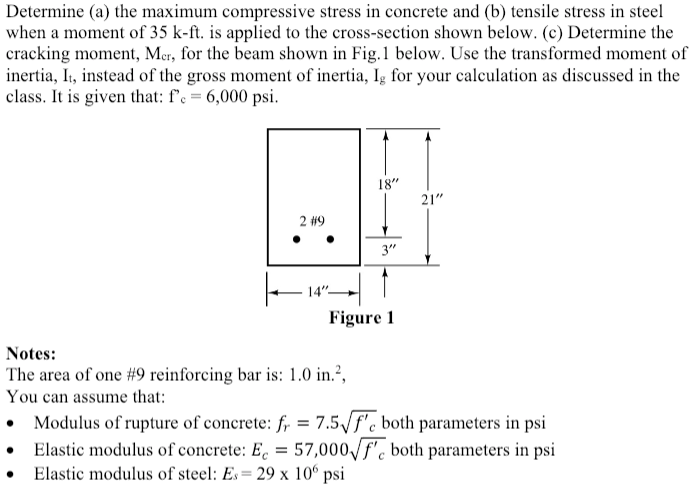

Concrete Structures

While concrete is strong in compression, it is weak in tension. Therefore, the maximum tensile stress is a critical design parameter for concrete structures such as bridges and dams. Reinforcement steel is often used to resist tensile stresses. Understanding the stress distribution in concrete members is crucial for determining the required amount and placement of reinforcement.

Example: In a reinforced concrete beam, the concrete primarily resists compressive stresses, while the steel reinforcement resists tensile stresses. Cracking occurs in concrete when the tensile stress exceeds its tensile strength. By calculating the maximum tensile stress in the concrete and ensuring that it is below the cracking stress, and by designing the steel reinforcement to carry the tensile load effectively, engineers can prevent premature cracking and ensure the long-term durability of the structure.

Pressure Vessels

Pressure vessels, such as those used in chemical plants and power plants, are designed to contain fluids or gases under high pressure. The walls of a pressure vessel are subjected to tensile stresses, both in the hoop direction (circumferential) and the longitudinal direction (axial).

Example: For a thin-walled cylindrical pressure vessel, the hoop stress (σh) and longitudinal stress (σl) can be approximated as

σh = (Pr)/t

σl = (Pr)/(2t)

Where:

P is the internal pressure

r is the radius of the vessel

t is the wall thickness

The maximum stress in this case is typically the hoop stress, which is twice the longitudinal stress. Engineers use these formulas to determine the required wall thickness of the pressure vessel to ensure that the maximum stress remains below the allowable stress for the vessel material, considering safety factors and code requirements. Failure to properly account for maximum stress can lead to catastrophic ruptures.

Geotechnical Engineering

In geotechnical engineering, the maximum stress is crucial for analyzing soil stability and designing foundations. Soil is subjected to vertical stress due to the weight of overlying soil and structures, as well as horizontal stress due to lateral earth pressure.

Example: When designing a foundation for a building, engineers must determine the stress distribution in the soil beneath the foundation. The vertical stress increases with depth, while the horizontal stress depends on the soil properties and the presence of any retaining structures. By calculating the maximum stress in the soil and comparing it to the soil's bearing capacity, engineers can ensure that the foundation will not experience excessive settlement or shear failure.

Considerations and Failure Theories

Determining the maximum stress is only one part of the design process. It's essential to compare the maximum stress to the material's strength to predict whether failure will occur. Several failure theories are used for this purpose:

Maximum Principal Stress Theory

This theory predicts failure when the maximum principal stress (σ1) exceeds the material's tensile strength (σt) or compressive strength (σc). It's a simple theory but not always accurate for ductile materials.

Maximum Shear Stress Theory (Tresca Criterion)

This theory states that failure occurs when the maximum shear stress (τmax) exceeds the material's shear strength (τy/2, where τy is the shear yield strength). This theory is more conservative than the maximum principal stress theory and is often used for ductile materials.

Distortion Energy Theory (von Mises Criterion)

This theory, also known as the von Mises criterion, predicts failure when the distortion energy per unit volume exceeds the distortion energy at yield. The von Mises stress (σv) is calculated as:

σv = √[0.5((σx - σy)^2 + (σy - σz)^2 + (σz - σx)^2) + 3(τxy^2 + τyz^2 + τzx^2)]

Failure occurs when σv exceeds the material's yield strength (σy). The von Mises criterion is widely used for ductile materials because it accurately predicts yielding under multiaxial stress states.

Example Calculation: Applying Von Mises Criterion

Let's say a steel component is subjected to the following stresses: σx = 100 MPa, σy = 50 MPa, and τxy = 30 MPa. The material has a yield strength of σy = 250 MPa. We want to determine if the component will yield according to the von Mises criterion.

First, we calculate the principal stresses:

σ1,2 = (100 + 50)/2 ± √[((100 - 50)/2)^2 + 30^2]

σ1,2 = 75 ± √(25^2 + 30^2)

σ1,2 = 75 ± √(625 + 900)

σ1,2 = 75 ± √1525

σ1 = 75 + 39.05 =

114.05 MPa

σ2 = 75 - 39.05 =

35.95 MPa

Since we are using the Von Mises criterion, we need σv. Here, σz, τyz, and τzx are zero. Thus,

σv = √[0.5((100 - 50)^2 + (50 - 0)^2 + (0 - 100)^2) + 3(30^2 + 0 + 0)]

σv = √[0.5(2500 + 2500 + 10000) + 3(900)]

σv = √[0.5(15000) + 2700]

σv = √(7500 + 2700)

σv = √10200

σv ≈ 101 MPa

Since σv (101 MPa) is less than σy (250 MPa), the component will not yield according to the von Mises criterion.

Common Pitfalls and Misconceptions

Ignoring Stress Concentrations: Sharp corners, holes, and other geometric discontinuities can significantly increase stress levels. These stress concentrations must be considered in the design process, often through finite element analysis (FEA). Using Engineering Stress Instead of True Stress: Engineering stress is calculated using the original cross-sectional area, while true stress is calculated using the instantaneous cross-sectional area. For large deformations, true stress provides a more accurate representation of the material's behavior. Applying Simplified Formulas to Complex Geometries: The simple stress formulas (σ = F/A, σ = My/I) are derived based on specific assumptions. Applying these formulas to complex geometries or loading conditions can lead to significant errors. FEA is often necessary for accurate stress analysis in such cases. Neglecting Residual Stresses: Manufacturing processes such as welding and heat treatment can introduce residual stresses into a material. These residual stresses can significantly affect the material's strength and fatigue life. Confusion Between Stress and Strength:Stress is the internal resistance to an applied load, while strength is the material's ability to withstand stress before failure. The allowable stress is a fraction of the material's strength, providing a safety factor.

People Also Ask

How do you calculate hoop stress in thin-walled cylinders?

Hoop stress (σh) in a thin-walled cylinder is calculated using the formula: σh = (Pr)/t, where P is the internal pressure, r is the radius of the cylinder, and t is the wall thickness. This formula assumes that the wall thickness is significantly smaller than the radius (typically, t < r/10).

What is the difference between true stress and engineering stress?

Engineering stress is calculated using the original cross-sectional area of the material, while true stress is calculated using the instantaneous cross-sectional area. True stress provides a more accurate representation of the material's behavior, especially at large strains where the cross-sectional area changes significantly.

When should principal stress formulas be applied in design?

Principal stress formulas should be applied when a material is subjected to combined loading, meaning normal and shear stresses are acting simultaneously. They are crucial for determining the maximum normal and shear stresses the material experiences, regardless of the plane's orientation, and are essential for accurate failure prediction using theories like the von Mises criterion or the maximum shear stress theory.

Conclusion

The maximum stress formula is a fundamental tool in construction and mechanical engineering. By understanding the principles of stress analysis, applying the appropriate formulas, and considering potential failure modes, engineers can design safe, reliable, and durable structures and components. Overlooking this critical step can lead to catastrophic failures and jeopardize public safety. Through a comprehensive understanding of stress analysis principles and meticulous application of the maximum stress formula, engineers contribute significantly to the integrity and longevity of the built environment.