Understanding stress distribution within structural components is paramount for ensuring their integrity and preventing failure. The ability to identify and calculate the maximum stress at critical points is a fundamental skill for any engineer involved in design, analysis, or maintenance. This article delves into the crucial formulas and methodologies used to determine maximum stress, highlighting their application in various engineering scenarios.

Identifying Critical Stress Locations and the Importance of Maximum Stress

Before delving into specific formulas, it’s crucial to understandwhyidentifying maximum stress is so important. All materials have a finite strength – a limit beyond which they will permanently deform or fracture. This strength is often characterized by yield strength (the point at which permanent deformation begins) and ultimate tensile strength (the point at which fracture occurs). If the maximum stress within a component exceeds these values, the component is at risk of failure.

Critical stress locations are typically found where geometric discontinuities or stress concentrations exist. These can include:

Holes or cutouts

Corners (especially sharp corners)

Changes in cross-section

Points of applied load

Welds or other joints

By accurately determining the maximum stress at these critical locations, engineers can assess the structural integrity of a component, optimize its design to reduce stress concentrations, and select appropriate materials to withstand the applied loads. Furthermore, it's essential to consider different types of stress, such as tensile, compressive, shear, and torsional, as the location and magnitude of maximum stress will vary depending on the loading conditions.

Normal Stress Formulas: Axial and Bending

Normal stress is a force acting perpendicular to a surface. It can be either tensile (pulling) or compressive (pushing). Two common scenarios involving normal stress are axial loading and bending.

Axial Stress

When a force (F) is applied axially to a member with a cross-sectional area (A), the normal stress (σ) is calculated as:

σ = F/A

This formula assumes that the force is uniformly distributed across the cross-section. In reality, stress concentrations can occur near the point of load application, so this is often a simplified model.

Example: A steel rod with a diameter of 20 mm is subjected to a tensile force of 50 k N. Calculate the axial stress in the rod.

First, calculate the cross-sectional area: A = πr² = π(0.01 m)² ≈

3.14 x 10⁻⁴ m²

Then, calculate the stress: σ = (50 x 10³ N) / (3.14 x 10⁻⁴ m²) ≈

159.2 MPa

Bending Stress

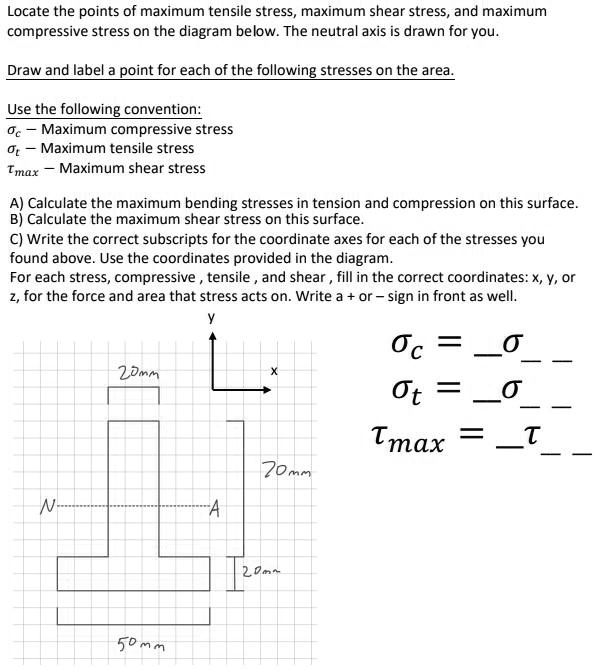

Bending stress occurs in beams subjected to bending moments. The maximum bending stress (σ_max) occurs at the outermost fibers of the beam and is calculated using the flexure formula:

σ_max = My/I

Where:

M is the bending moment at the section of interest.

y is the distance from the neutral axis to the outermost fiber.

I is the area moment of inertia of the cross-section about the neutral axis.

Example: A rectangular beam with a width of 50 mm and a height of 100 mm is subjected to a bending moment of 10 k N·m. Calculate the maximum bending stress.

First, calculate the area moment of inertia: I = (bh³) / 12 = (0.05 m)(0.1 m)³ / 12 ≈

4.17 x 10⁻⁶ m⁴

Then, calculate the distance from the neutral axis to the outermost fiber: y = h/2 = 0.1 m / 2 =

0.05 m

Finally, calculate the maximum bending stress: σ_max = (10 x 10³ N·m)(0.05 m) / (4.17 x 10⁻⁶ m⁴) ≈

119.9 MPa

How does the shape of a beam's cross-section influence the maximum bending stress?

The shape of a beam’s cross-section significantly impacts the maximum bending stress through its area moment of inertia (I). A larger I indicates a greater resistance to bending, resulting in lower bending stress for a given bending moment. Therefore, shapes that place more material further away from the neutral axis, such as I-beams and box beams, are more efficient at resisting bending compared to solid rectangular beams with the same cross-sectional area.

Shear Stress Formulas: Direct and Torsional

Shear stress is a force acting parallel to a surface. Like normal stresses, it's critical to identify the location and magnitude of peak shear stresses.

Direct Shear Stress

Direct shear stress (τ) occurs when a force (V) is applied parallel to a surface with an area (A). The formula is:

τ = V/A

This formula assumes uniform shear stress distribution, which may not always be the case, especially near the edges of the shear area.

Example: A bolt with a diameter of 10 mm is used to connect two plates subjected to a shear force of 5 k N. Calculate the shear stress in the bolt.

First, calculate the shear area: A = πr² = π(0.005 m)² ≈

7.85 x 10⁻⁵ m²

Then, calculate the shear stress: τ = (5 x 10³ N) / (7.85 x 10⁻⁵ m²) ≈

63.7 MPa

Torsional Shear Stress

Torsional shear stress occurs in shafts subjected to a torque (T). The maximum torsional shear stress (τ_max) occurs at the outer surface of the shaft and is calculated as:

τ_max = Tr/J

Where:

T is the applied torque.

r is the radius of the shaft.

J is the polar moment of inertia of the cross-section. For a solid circular shaft, J = (πd⁴)/32, where d is the diameter.

Example: A solid circular shaft with a diameter of 50 mm is subjected to a torque of 2 k N·m. Calculate the maximum torsional shear stress.

First, calculate the polar moment of inertia: J = (π(0.05 m)⁴)/32 ≈

6.14 x 10⁻⁷ m⁴

Then, calculate the maximum torsional shear stress: τ_max = (2 x 10³ N·m)(0.025 m) / (6.14 x 10⁻⁷ m⁴) ≈

81.4 MPa

What are common assumptions made when calculating torsional shear stress, and how can they affect accuracy?

Common assumptions include a perfectly circular cross-section, linear elastic material behavior, and uniform torque distribution along the shaft's length. Deviations from these assumptions, such as non-circular cross-sections, plastic deformation, or stress concentrations due to keyways or other geometric features, can significantly affect the accuracy of the calculated torsional shear stress. More advanced analysis techniques, like finite element analysis, may be required for complex geometries or loading conditions.

Stress Concentrations: The Impact of Geometry

Stress concentrations occur at points where the geometry of a component changes abruptly, such as at holes, fillets, or corners. The presence of a stress concentration significantly increases the local stress compared to the nominal stress calculated using simple formulas.

To account for stress concentrations, a stress concentration factor (K) is introduced. The maximum stress (σ_max) at the stress concentration is then calculated as:

σ_max = Kσ_nom

Where σ_nom is the nominal stress calculated without considering the stress concentration. The value of K depends on the geometry of the discontinuity and the type of loading. Stress concentration factors are typically obtained from charts or handbooks based on experimental data or finite element analysis.

Example: A flat plate with a width of 100 mm and a thickness of 10 mm has a central hole with a diameter of 20 mm. The plate is subjected to a tensile force of 10 k N. The stress concentration factor at the edge of the hole is 3. Calculate the maximum stress at the hole.

First, calculate the nominal stress: σ_nom = F/A = (10 x 10³ N) / ((0.1 m -

0.02 m)(0.01 m)) ≈

12.5 MPa

Then, calculate the maximum stress: σ_max = Kσ_nom = 3 12.5 MPa =

37.5 MPa

It's critical to understand that stress concentrations are localized phenomena. The stress decreases rapidly with distance from the discontinuity. Also, it's important to note that under static loading of ductile materials, the effect of stress concentrations might be reduced due to local yielding, a phenomenon known as stress redistribution. However, under fatigue loading, stress concentrations are much more significant and can lead to premature failure.

Combined Stresses: Superposition and Mohr's Circle

In many engineering applications, components are subjected to multiple types of stress simultaneously. For example, a shaft might experience both bending and torsion. In such cases, it's necessary to combine the individual stresses to determine the maximum stress at a critical point.

The principle of superposition can be used to combine normal stresses and shear stresses that act on the same plane. However, this principle is only valid if the stresses are linearly elastic and the deformations are small.

To determine the maximum normal and shear stresses when multiple stresses are present, Mohr's circle is a powerful graphical tool. Mohr's circle allows engineers to visualize the stress state at a point and determine the principal stresses (the maximum and minimum normal stresses) and the maximum shear stress.

The principal stresses (σ₁ and σ₂) can be calculated using the following formulas:

σ₁,₂ = (σx + σy)/2 ± √(((σx - σy)/2)² + τxy²)

Where: σx is the normal stress in the x-direction. σy is the normal stress in the y-direction. τxy is the shear stress in the xy-plane.

The maximum shear stress (τ_max) is given by:

τ_max = √(((σx - σy)/2)² + τxy²)

The orientation of the principal stresses can also be determined from Mohr's circle.

How do you calculate hoop stress in thin-walled cylinders?

Hoop stress (σ_h), also known as circumferential stress, in a thin-walled cylinder subjected to internal pressure (p) is calculated using the formula: σ_h = (pr)/t, where 'r' is the radius of the cylinder and 't' is the wall thickness. This formula assumes that the wall thickness is significantly smaller than the cylinder's radius (typically, t < r/10).

What is the difference between true stress and engineering stress?

Engineering stress is calculated by dividing the applied force by the original cross-sectional area of the material, while true stress is calculated by dividing the applied force by the instantaneous cross-sectional area of the material during deformation. True stress provides a more accurate representation of the stress experienced by the material as it deforms, particularly at large strains where the cross-sectional area changes significantly. Engineering stress is simpler to calculate but less accurate at higher strains.

Finite Element Analysis (FEA)

While the formulas presented above provide a good understanding of stress distribution in simple geometries and loading conditions, they may not be sufficient for complex structures or loading scenarios. In such cases, Finite Element Analysis (FEA) is a powerful tool for determining stress distributions and identifying critical stress locations.

FEA involves dividing a structure into a large number of small elements and then solving the governing equations for each element. This allows engineers to accurately predict the stress distribution, deformation, and other structural responses of a component under complex loading conditions. FEA software packages are widely available and provide a valuable tool for design optimization and failure analysis.

Conclusion

Determining maximum stress at critical structural points is a fundamental aspect of engineering design and analysis. By understanding the underlying principles and applying the appropriate formulas and methodologies, engineers can ensure the structural integrity of components and prevent failures. While simplified formulas are useful for initial estimates, more complex scenarios often require the use of FEA to accurately predict stress distributions and identify critical stress locations. Continual learning and development in stress analysis techniques are vital for engineers to create safe, reliable, and efficient designs.