Understanding and mitigating thermal stress is paramount in the design and operation of nuclear power plants. These facilities operate under extreme conditions, generating immense heat through nuclear fission. This heat, while essential for power generation, also creates significant temperature gradients within structural components, leading to thermal stresses. If not properly accounted for, these stresses can lead to component failure, jeopardizing the safety and efficiency of the entire plant. This article provides a comprehensive overview of thermal stress, focusing on the formulas and considerations vital for nuclear power plant applications.

Thermal Stress Fundamentals

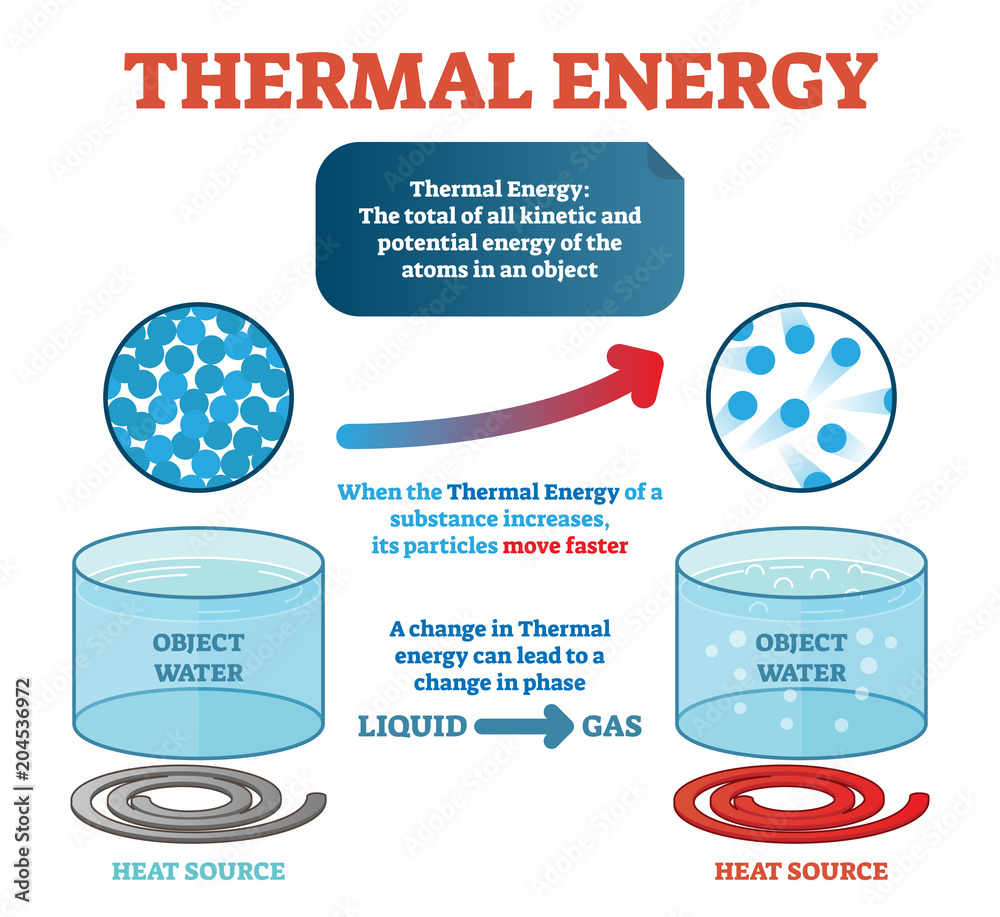

Thermal stress arises when a material is subjected to a temperature change while its expansion or contraction is constrained. The fundamental principle behind thermal stress is the material's tendency to expand or contract with temperature changes. This natural tendency is quantified by the coefficient of thermal expansion, α, which represents the fractional change in length per degree Celsius (or Fahrenheit) change in temperature. When a component is restrained, this expansion or contraction is prevented, leading to internal stresses within the material.

The simplest thermal stress scenario involves a uniform temperature change, ΔT, in a material with a coefficient of thermal expansion, α, and a Young's modulus, E. If the material were free to expand, it would experience a strain, ε, given by:

ε = αΔT

However, if the material is completely constrained, this strain is prevented, resulting in a stress, σ, given by:

σ = Eε = EαΔT

This equation represents the basic thermal stress formula for a constrained material experiencing a uniform temperature change. Note that this formula assumes a linear elastic material behavior. For more complex situations, such as non-uniform temperature distributions or plastic deformation, more sophisticated analysis techniques are required.

Thermal Stress in Nuclear Reactor Components

Nuclear reactors contain numerous components susceptible to thermal stress, including: Reactor Pressure Vessel (RPV): The RPV houses the reactor core and is subjected to high temperatures and pressures. Non-uniform heating from the core can create significant thermal gradients, particularly during reactor startup and shutdown. Piping Systems: Piping systems transport coolant (typically water or liquid metal) throughout the plant. Temperature fluctuations in the coolant can induce thermal stress in the pipes, especially at bends and junctions. Fuel Rods: Fuel rods contain the nuclear fuel and are directly heated by nuclear fission. The temperature difference between the center and the surface of the fuel rod can be substantial, leading to significant thermal stresses within the fuel and cladding. Steam Generators: Steam generators transfer heat from the reactor coolant to produce steam. Thermal stress can occur due to temperature differences between the hot reactor coolant and the cooler water in the steam generator.

The complex geometries and operating conditions of these components necessitate the use of advanced stress analysis techniques, such as finite element analysis (FEA), to accurately predict thermal stress distributions.

Formulas for Common Geometries

While the fundamental thermal stress formula (σ = EαΔT) provides a starting point, specific formulas are available for common geometries encountered in nuclear power plants.

Thin-Walled Cylinders (Piping)

Thin-walled cylinders, such as pipes, are prevalent in nuclear facilities. When subjected to a uniform temperature change, the hoop stress (σh) and axial stress (σa) can be approximated using the following formulas:

σh = EαΔT / (1 - ν)

σa = EαΔT / (1 - ν)

where ν is Poisson's ratio. These formulas assume that the cylinder is free to expand axially. If the cylinder is constrained axially, the axial stress will increase.

Thick-Walled Cylinders (Reactor Pressure Vessel)

For thick-walled cylinders, such as the RPV, the stress distribution is more complex and depends on the radial position. When subjected to an internal pressure (p) and a temperature gradient, the radial stress (σr) and tangential stress (σθ) can be calculated using Lame's equations, modified to include the thermal stress component.

σr = A - B/r2 + σt,r

σθ = A + B/r2 + σt,θ

Where A and B are constants determined by the boundary conditions (e.g., pressure at the inner and outer surfaces) and σt,r and σt,θ represent the thermal stress components in the radial and tangential directions, respectively. Calculating these thermal stress components requires integrating the temperature distribution across the cylinder wall. The general form of the thermal stress component is:

σt = - (Eα / (1 - ν) ) ( (1/r2) ∫ar T(r)r dr - ( (r2 - a2) / (b2 - a2) ) (1/b2) ∫ab T(r)r dr )

Where T(r) is the temperature as a function of radial position 'r', 'a' is the inner radius, and 'b' is the outer radius. Evaluating this integral can be challenging and often requires numerical methods or simplifying assumptions about the temperature distribution.

Beams and Plates

Thermal bending stresses occur in beams and plates subjected to non-uniform temperature distributions through their thickness. The thermal moment (MT) is given by:

MT = ∫ EαT(z)z dz

where the integration is performed over the thickness of the beam or plate, and z is the distance from the neutral axis. The resulting bending stress is then:

σ = MTz / I

where I is the second moment of area of the cross-section.

Example Calculation: Thermal Stress in a Pipe

Consider a stainless steel pipe with an outer diameter of 100 mm and a wall thickness of 5 mm. The pipe is subjected to a uniform temperature increase of 100 °C. The material properties are:

E = 200 GPa α = 17.3 x 10-6 / °C ν =

0.3

Assuming the pipe is constrained from axial expansion, we can calculate the hoop stress and axial stress using the thin-walled cylinder formulas:

σh = σa = (200 x 109 Pa) (17.3 x 10-6 / °C) (100 °C) / (1 -

0.3) =

49.43 MPa

This example demonstrates the magnitude of thermal stress that can arise from even a moderate temperature change.

Mitigation Strategies

Several strategies can be employed to mitigate thermal stress in nuclear power plants: Material Selection: Choosing materials with lower coefficients of thermal expansion can reduce thermal stress. Thermal Insulation: Applying thermal insulation can minimize temperature gradients and reduce heat transfer. Expansion Joints: Incorporating expansion joints in piping systems allows for thermal expansion and contraction without inducing significant stress. Preheating: Preheating components before operation can reduce thermal shock and stress during startup. Controlled Heating and Cooling Rates: Implementing controlled heating and cooling rates minimizes temperature gradients and reduces thermal stress. Stress Relief Annealing: Post-weld heat treatment can reduce residual stresses, including thermal stresses introduced during welding.

Considerations for Creep and Fatigue

At the high operating temperatures of nuclear power plants, creep and fatigue become significant concerns. Creep is the time-dependent deformation of a material under sustained stress, while fatigue is the weakening of a material due to repeated loading. Thermal stress can contribute to both creep and fatigue, especially in components subjected to cyclic temperature variations.

The ASME Boiler and Pressure Vessel Code, Section III, provides guidelines for assessing creep and fatigue damage in nuclear components. These guidelines involve calculating cumulative damage factors based on the stress history and material properties. It's crucial to consider the combined effects of thermal stress, pressure stress, and other loading conditions when evaluating the long-term integrity of nuclear components.

Common Pitfalls and Misconceptions

Assuming Uniform Temperature Distribution: In reality, temperature distributions are rarely uniform. Using the simplified thermal stress formula (σ = EαΔT) with an average temperature change can lead to significant errors. Neglecting Stress Concentrations: Stress concentrations occur at geometric discontinuities, such as holes, corners, and welds. Thermal stress can be amplified at these locations, increasing the risk of failure. Ignoring Plastic Deformation: The thermal stress formulas presented here are based on linear elastic material behavior. If the stress exceeds the yield strength of the material, plastic deformation will occur, and the stress distribution will change. Overlooking Creep and Fatigue: As mentioned earlier, creep and fatigue can significantly reduce the lifespan of components subjected to thermal stress at high temperatures. Inadequate Finite Element Modeling:Using coarse meshes or inappropriate element types in FEA can lead to inaccurate stress predictions.

Conclusion

Thermal stress is a critical consideration in the design and operation of nuclear power plants. Understanding the underlying principles, applying appropriate formulas, and implementing effective mitigation strategies are essential for ensuring the safety and reliability of these complex facilities. By considering the factors discussed in this article, engineers can minimize the risk of thermal stress-induced failures and maintain the integrity of nuclear power plant components. Continuous monitoring and advanced analysis techniques are also crucial for detecting and addressing potential thermal stress problems throughout the plant's operational life.

How do you calculate the thermal stress when expansion is partially constrained?

When expansion is partially constrained, the resulting stress will be less than the stress calculated for full constraint. The calculation requires determining the actual amount of expansion that occurs. This often involves analyzing the stiffness of the constraint and the thermal expansion of the component. You then use the reduced expansion value in the stress calculation. Finite element analysis is often used for these types of problems.

What materials are best for minimizing thermal stress in high-temperature nuclear applications?

Materials with low coefficients of thermal expansion, high thermal conductivity, and high strength at elevated temperatures are preferred. Examples include certain grades of stainless steel, nickel-based alloys (such as Inconel), and specialized ceramics. The selection depends on the specific operating conditions and the required mechanical properties.

How does radiation embrittlement affect thermal stress calculations in reactor pressure vessels?

Radiation embrittlement reduces the ductility and toughness of the RPV steel, making it more susceptible to brittle fracture under thermal stress. This means that the allowable stress limits must be reduced to account for the increased risk of fracture. Fracture mechanics analyses, incorporating the effects of radiation embrittlement, are often used to assess the integrity of the RPV.