Thermal stress, an often-overlooked but critically important phenomenon, arises when temperature changes induce expansion or contraction in a material that is constrained from freely deforming. This constraint results in internal stresses that can lead to yielding, fracture, or other forms of structural failure if not properly accounted for in design and analysis. Understanding the thermal stress formula and its applications is paramount in ensuring the reliability and longevity of various engineering structures and components across numerous industries.

Understanding the Thermal Stress Formula

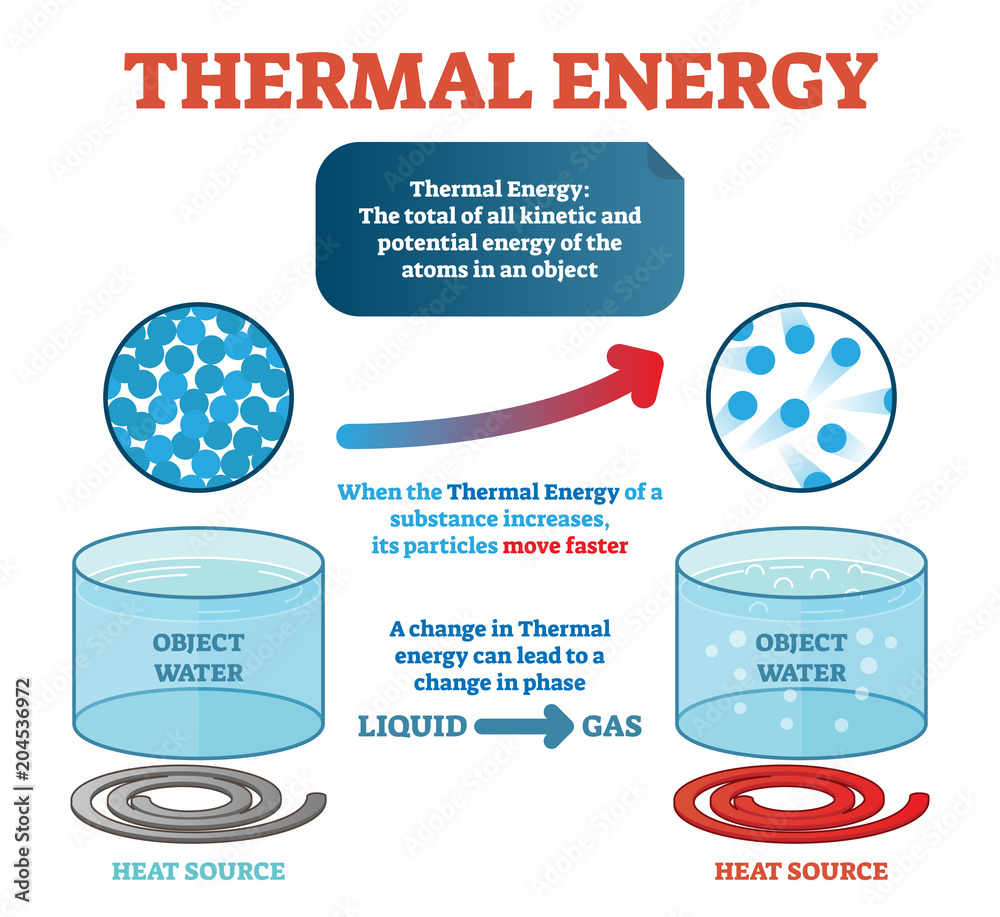

The fundamental principle behind thermal stress is that materials expand when heated and contract when cooled. The amount of expansion or contraction is proportional to the temperature change, the material's coefficient of thermal expansion (α), and the original length of the material. When this expansion or contraction is restricted, internal stresses develop. The thermal stress formula, in its simplest form, expresses the relationship between temperature change (ΔT), coefficient of thermal expansion (α), and Young's modulus (E) to determine the resulting stress (σ).

The basic formula for thermal stress (σ) in a constrained, linear elastic material is:

σ = EαΔT

Where: σ is the thermal stress (typically in Pascals (Pa) or pounds per square inch (psi)).

E is Young's modulus of elasticity (typically in Pa or psi), representing the material's stiffness. α is the coefficient of linear thermal expansion (typically in 1/°C or 1/°F), representing how much the material expands or contracts per degree of temperature change. ΔT is the change in temperature (typically in °C or °F).

It’s important to note the sign convention. A positive ΔT (increase in temperature) will result in compressive stress (negative σ) if the material is constrained from expanding. Conversely, a negative ΔT (decrease in temperature) will result in tensile stress (positive σ) if the material is constrained from contracting.

This formula assumes uniaxial stress and a uniform temperature distribution. In reality, situations can be much more complex, involving biaxial or triaxial stresses, non-uniform temperature distributions, and material nonlinearities. These complexities require more sophisticated analysis techniques, such as finite element analysis (FEA).

Factors Affecting Thermal Stress

Several factors can significantly influence the magnitude and distribution of thermal stresses: Material Properties: The coefficient of thermal expansion and Young's modulus are crucial material properties. Materials with high coefficients of thermal expansion will experience larger stresses for the same temperature change. Similarly, stiffer materials (higher Young's modulus) will experience higher stresses. Temperature Gradient: Non-uniform temperature distributions create thermal gradients, leading to differential expansion and contraction within the material. This can result in complex stress patterns, often concentrated at locations with the highest temperature gradients. Geometry and Constraints: The shape of the object and the way it's constrained play a vital role. Geometries with sharp corners or abrupt changes in cross-section are prone to stress concentrations. The type of constraint (e.g., fixed, pinned, sliding) significantly affects the distribution of thermal stresses. Material Behavior: The simple formula assumes linear elastic behavior. However, at higher temperatures or stresses, materials may exhibit plastic deformation (yielding) or creep, which can redistribute stresses and reduce their magnitude.

Industrial Applications of the Thermal Stress Formula

The thermal stress formula finds extensive application in various industrial settings, particularly in the design and analysis of components subjected to significant temperature variations.

Pressure Vessels

Pressure vessels, used extensively in the chemical, petrochemical, and power generation industries, are subject to both pressure-induced stresses and thermal stresses. During operation, the vessel walls can experience significant temperature gradients due to the hot fluid or gas contained within.

The thermal stress formula helps engineers assess the additional stresses induced by these temperature variations. For example, consider a steel pressure vessel operating at high temperature. The inner surface, exposed to the hot fluid, will be hotter than the outer surface. This temperature difference creates a thermal gradient through the wall thickness, leading to compressive stresses on the inner surface and tensile stresses on the outer surface. These thermal stresses must be considered in addition to the pressure-induced hoop and longitudinal stresses to ensure the vessel's structural integrity.

Pipelines

Pipelines transporting hot fluids, such as steam or oil, are also susceptible to thermal stresses. The expansion of the pipe due to the elevated temperature is constrained by the supports and anchors along its length, resulting in axial compressive stresses. Expansion loops or expansion joints are often incorporated into pipeline designs to accommodate thermal expansion and reduce the magnitude of thermal stresses.

The thermal stress formula can be used to calculate the required size and spacing of expansion loops. By determining the amount of thermal expansion and the allowable stress in the pipe material, engineers can design the expansion loops to absorb the expansion without exceeding the material's yield strength.

Heat Exchangers

Heat exchangers, designed to transfer heat between two fluids, experience significant temperature differences between their various components. The tubes, shell, and tube sheets can all be at different temperatures, leading to complex thermal stress patterns. These stresses can cause tube bowing, cracking of tube sheets, and failure of welded joints.

Detailed thermal stress analysis, often using FEA, is crucial in heat exchanger design. The analysis must consider the temperature distribution, material properties, and the geometry of the exchanger to predict the stresses and ensure the exchanger's reliability.

Aerospace Components

Aerospace components, such as turbine blades in jet engines, are subjected to extreme temperature gradients and high centrifugal loads. The hot gases impinging on the turbine blades create significant thermal stresses, especially at the leading and trailing edges. These stresses, combined with the centrifugal stresses, can lead to creep, fatigue, and eventual failure of the blades.

Advanced cooling techniques, such as film cooling and internal cooling channels, are employed to reduce the temperature gradients and mitigate thermal stresses in turbine blades. The thermal stress formula, along with more advanced analysis methods, is used to optimize the cooling designs and predict the life of the blades.

Electronic Devices

Even in the realm of electronics, thermal stresses play a critical role. The components in electronic devices generate heat during operation. This heat can cause temperature gradients within the device, leading to thermal stresses in the circuit boards, solder joints, and integrated circuits. These stresses can cause premature failure of the components, especially in devices subjected to repeated thermal cycling (powering on and off).

Careful thermal management, including the use of heat sinks, thermal interface materials, and optimized circuit board layouts, is essential in electronic device design to minimize thermal stresses and improve reliability.

Worked Examples

Example 1: Constrained Steel Bar

A steel bar, 1 meter long, is fixed at both ends. The bar is initially at 20°C. Calculate the thermal stress in the bar if the temperature is increased to 100°C.

Given:

Length, L = 1 m

Initial Temperature, Ti = 20°C

Final Temperature, Tf = 100°C ΔT = Tf - Ti = 100°C - 20°C = 80°C

Coefficient of Thermal Expansion of Steel, α = 12 x 10-6 /°C

Young's Modulus of Steel, E = 200 GPa = 200 x 109 Pa

Using the thermal stress formula:

σ = EαΔT

σ = (200 x 109 Pa) x (12 x 10-6 /°C) x (80°C)

σ = 192 x 106 Pa = 192 MPa

The thermal stress in the steel bar is 192 MPa (compressive).

Example 2: Aluminum Plate with a Hole

An aluminum plate with a hole in the center is heated uniformly. Determine how the thermal stress concentrates around the hole.

While the simple formula is inadequate to fully capture the stress concentration, we can understand the principle. The hole acts as a geometric discontinuity. As the plate heats up, the material around the hole wants to expand. However, the presence of the hole disrupts the uniform stress distribution, leading to a stress concentration at the edge of the hole. A more accurate analysis would involve finite element analysis (FEA) to quantify the stress concentration factor. However, conceptually, the thermal expansion is magnified around the hole, leading to higher stresses than predicted by the basic formula alone.

Common Pitfalls and Misconceptions

Assuming Uniform Temperature: The thermal stress formula assumes a uniform temperature distribution. In reality, temperature gradients are common, especially in large structures or components subjected to localized heating. Ignoring temperature gradients can lead to significant errors in stress calculations. Neglecting Constraints: The type and location of constraints significantly affect the thermal stress distribution. Incorrectly modeling the constraints can lead to inaccurate results. Linear Elastic Assumption: The formula assumes that the material behaves linearly elastically. At high temperatures or stresses, materials may exhibit plastic deformation or creep. In such cases, more advanced material models and analysis techniques are required. Stress Concentration: Sharp corners and abrupt changes in cross-section can create stress concentrations, significantly increasing the local stresses. The basic thermal stress formula does not account for stress concentrations and may underestimate the actual stresses in these regions.

People Also Ask

How do you account for thermal stress in bolted joints?

Bolted joints are particularly susceptible to thermal stress issues. Differential thermal expansion between the bolt and the clamped materials can lead to changes in preload, potentially causing joint loosening or failure. Selecting bolt materials with similar thermal expansion coefficients to the clamped materials helps minimize this effect. Furthermore, Belleville washers can be used to maintain a more consistent preload despite thermal expansion differences. Accurate thermal stress analysis, often using FEA, is critical in designing robust bolted joints for high-temperature applications.

What is the impact of thermal cycling on fatigue life?

Thermal cycling, the repeated heating and cooling of a component, can significantly reduce its fatigue life. Each cycle induces thermal stresses that, even if below the yield strength, can accumulate damage over time, leading to fatigue crack initiation and propagation. The magnitude of the temperature variation, the cycle frequency, and the material's fatigue properties all influence the component's fatigue life under thermal cycling. Understanding the thermal stress range during each cycle is crucial for accurately predicting fatigue life using S-N curves or other fatigue analysis methods.

When should FEA be used for thermal stress analysis?

Finite element analysis (FEA) is recommended when the geometry is complex, the temperature distribution is non-uniform, the constraints are complicated, or when the material behavior is nonlinear. The basic thermal stress formula is only applicable to simple geometries and uniform temperature distributions. FEA provides a more accurate and comprehensive analysis, allowing engineers to account for complex stress patterns, stress concentrations, and nonlinear material behavior. It is particularly useful for optimizing designs and identifying potential failure locations.

In conclusion, the thermal stress formula provides a fundamental understanding of how temperature changes can induce stresses in constrained materials. While the basic formula has limitations, it serves as a valuable starting point for engineers. By understanding the factors affecting thermal stress, recognizing common pitfalls, and utilizing more advanced analysis techniques when necessary, engineers can effectively mitigate the risks associated with thermal stress and ensure the reliability and longevity of engineering structures and components in a wide range of industrial applications.