Torsional Stress Formula for Solid and Hollow Shafts: A Comprehensive Guide

Torsional stress, a critical concept in mechanical engineering, arises when a twisting force, or torque, is applied to an object, causing it to deform by twisting. Understanding and calculating torsional stress is paramount in the design and analysis of shafts, axles, and other components that transmit rotational power. This article provides a comprehensive overview of the torsional stress formula for both solid and hollow shafts, covering the underlying principles, derivations, practical applications, and potential pitfalls. Whether you're an engineering student, a practicing engineer, or a researcher, this guide will equip you with the knowledge to confidently tackle torsional stress problems.

Understanding Torsional Stress

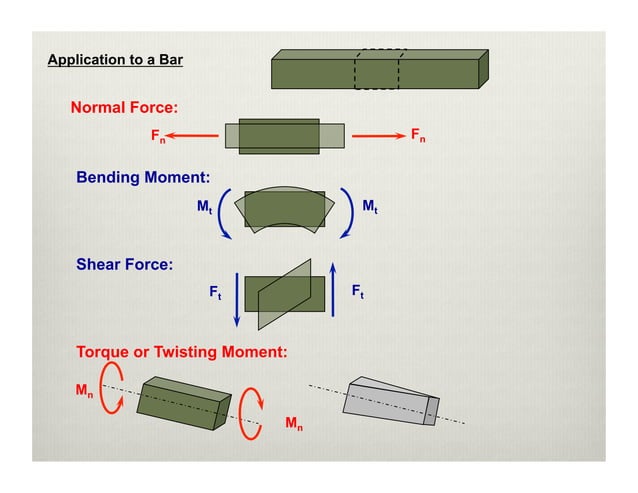

Torsional stress is a shear stress that develops within a material when subjected to a torque. Imagine twisting a cylindrical rod – the internal stresses resisting this twisting action are torsional stresses. This type of stress is crucial in applications involving rotating machinery, such as drive shafts in automobiles, power transmission systems, and axles in various equipment. The magnitude of the torsional stress depends on the applied torque, the geometry of the shaft (specifically its cross-sectional area), and the material's resistance to twisting (its shear modulus).

Unlike tensile or compressive stress, which act perpendicular to a surface, torsional stress acts parallel to the cross-sectional area of the shaft. This shear stress is zero at the center of the shaft and increases linearly to a maximum value at the outer surface. This distribution is fundamental to understanding why hollow shafts can be more efficient than solid shafts for certain applications.

The Torsional Stress Formula for Solid Shafts

The torsional stress formula for a solid circular shaft is given by:

τ = (T r) / J

Where: τ (tau) is the torsional shear stress (usually expressed in Pascals (Pa) or pounds per square inch (psi)).

T is the applied torque (usually expressed in Newton-meters (N·m) or pound-feet (lb·ft)).

r is the radial distance from the center of the shaft to the point where the stress is being calculated (usually expressed in meters (m) or inches (in)). The maximum stress occurs whenris equal to the radius of the shaft.

J is the polar moment of inertia of the shaft's cross-section (usually expressed in meters to the fourth power (m4) or inches to the fourth power (in4)). For a solid circular shaft, J = (π d4) / 32, where d is the diameter of the shaft. Alternatively, J = (π r4) / 2, where r is the radius.

This formula assumes the following:

The shaft is made of a homogeneous and isotropic material (meaning its properties are the same throughout and in all directions).

The shaft is circular in cross-section.

The applied torque is static or varies slowly with time.

The stress is within the elastic limit of the material (meaning the material will return to its original shape when the torque is removed).

Example Calculation: Solid Shaft

A solid steel shaft with a diameter of 50 mm is subjected to a torque of 500 N·m. Calculate the maximum torsional shear stress in the shaft.

1.Identify the given parameters:

T = 500 N·m

d = 50 mm = 0.05 m

r = d/2 = 0.025 m

2.Calculate the polar moment of inertia (J):

J = (π d4) / 32 = (π (0.05 m)4) / 32 ≈

6.136 x 10-8 m4

3.Apply the torsional stress formula:

τ = (T r) / J = (500 N·m 0.025 m) / (6.136 x 10-8 m4) ≈

20.37 x 106 N/m2 =

20.37 MPa

Therefore, the maximum torsional shear stress in the shaft is approximately 20.37 MPa.

The Torsional Stress Formula for Hollow Shafts

Hollow shafts are often used in applications where weight reduction is critical. They offer a higher strength-to-weight ratio compared to solid shafts, as the material near the center of a solid shaft contributes little to its torsional strength. The torsional stress formula for a hollow circular shaft is similar to that of a solid shaft, but the polar moment of inertia is calculated differently:

τ = (T r) / J

Where: τ (tau) is the torsional shear stress.

T is the applied torque.

r is the radial distance from the center of the shaft to the point where the stress is being calculated. Themaximumstress occurs at theouterradius, ro. Theminimumstress occurs at theinnerradius, ri.

J is the polar moment of inertia of the hollow shaft's cross-section. For a hollow circular shaft, J = (π (do4 - di4)) / 32, where do is the outer diameter and di is the inner diameter. Alternatively, J = (π (ro4 - ri4)) / 2, where ro is the outer radius and ri is the inner radius.

Example Calculation: Hollow Shaft

A hollow steel shaft has an outer diameter of 80 mm and an inner diameter of 60 mm. It is subjected to a torque of 1000 N·m. Calculate the maximum torsional shear stress in the shaft.

1.Identify the given parameters:

T = 1000 N·m

do = 80 mm = 0.08 m

di = 60 mm = 0.06 m

ro = do/2 = 0.04 m

2.Calculate the polar moment of inertia (J):

J = (π (do4 - di4)) / 32 = (π ((0.08 m)4 - (0.06 m)4)) / 32 ≈

3.456 x 10-7 m4

3.Apply the torsional stress formula (using the outer radius for maximum stress):

τ = (T ro) / J = (1000 N·m 0.04 m) / (3.456 x 10-7 m4) ≈

115.74 x 106 N/m2 =

115.74 MPa

Therefore, the maximum torsional shear stress in the hollow shaft is approximately 115.74 MPa.

Key Considerations and Pitfalls

Stress Concentrations: The torsional stress formulas presented above assume a uniform cross-section. However, stress concentrations can occur at points of geometric discontinuity, such as keyways, holes, or sharp corners. These concentrations can significantly increase the local stress, potentially leading to premature failure. Stress concentration factors (found in engineering handbooks or determined through finite element analysis) must be applied in such cases.

Material Properties: The formulas assume that the material behaves linearly elastically. If the applied torque is high enough to cause plastic deformation, these formulas are no longer valid. In such cases, more advanced analysis techniques are required. Furthermore, temperature can significantly affect material properties; therefore, it's crucial to use material properties that are appropriate for the operating temperature.

Units: Ensure consistency in units. Using a mix of meters, millimeters, and Newton-meters will lead to incorrect results. Convert all values to a consistent system (e.g., SI units: meters, kilograms, seconds).

Assumptions: Always be aware of the assumptions underlying the formulas. For example, the formulas assume that the shaft is perfectly circular. If the shaft is slightly elliptical, the stress distribution will be more complex.

Combined Loading: In many real-world applications, shafts are subjected to combined loading, including torsion, bending, and axial loads. In these cases, it is necessary to combine the stresses using appropriate failure theories, such as the von Mises criterion or the Tresca criterion.

Real-World Applications

Understanding torsional stress is vital in a wide range of engineering applications: Drive Shafts:In automotive and aerospace engineering, drive shafts transmit power from the engine to the wheels. They are subjected to high torsional stresses, and their design must ensure sufficient strength and durability.

Axles: Axles in vehicles and machinery support weight and transmit torque. Understanding torsional stress is crucial for preventing axle failure.

Power Transmission Systems: Gearboxes, couplings, and other components in power transmission systems are subjected to torsional stresses. Accurate calculation of these stresses is essential for reliable operation.

Drilling Equipment: Drill strings used in oil and gas exploration are subjected to significant torsional stresses. Proper design and material selection are critical to prevent drill string failure deep underground.

Wind Turbine Blades: While primarily subject to bending, wind turbine blades also experience torsional forces, particularly during gusts of wind.

People Also Ask

How do you calculate the angle of twist due to torsion?

The angle of twist (θ) caused by torsion can be calculated using the formula: θ = (T L) / (G J), where T is the applied torque, L is the length of the shaft, G is the shear modulus of the material, and J is the polar moment of inertia. The angle of twist is usually expressed in radians. For small angles, the angle in radians can be converted to degrees by multiplying by 180/π.

What is the relationship between torsional stress and shear strain?

Torsional stress (τ) and shear strain (γ) are related by the shear modulus (G) of the material: τ = G γ. The shear modulus is a measure of a material's resistance to shear deformation. This linear relationship holds true within the elastic limit of the material.

When is it more advantageous to use a hollow shaft over a solid shaft?

Hollow shafts are generally preferred over solid shafts when weight is a critical design constraint, and the required torsional strength is relatively high. For a given weight, a hollow shaft can provide greater torsional strength than a solid shaft. This is because the material near the center of a solid shaft contributes little to its torsional strength, and this material can be removed without significantly reducing the shaft's load-carrying capacity. However, hollow shafts can be more expensive to manufacture and may be more susceptible to buckling under combined loading conditions.

Conclusion

The torsional stress formula is a fundamental tool in mechanical engineering for analyzing and designing shafts and other components subjected to twisting forces. Understanding the principles behind the formula, its limitations, and the factors that influence torsional stress is crucial for ensuring the safe and reliable operation of machinery and structures. By carefully considering the material properties, geometry, and loading conditions, engineers can effectively manage torsional stresses and prevent failures in a wide range of applications. Remember to account for stress concentrations and combined loading scenarios for a comprehensive and accurate analysis.