Torsional stress is a type of shear stress that arises in a material when it is subjected to a twisting force, or torque. Understanding torsional stress is crucial for designing shafts, axles, and other structural components that experience rotational loads. This article will delve into the torsional stress formula, its derivation, applications, and provide practical examples to solidify your understanding.

Understanding Torsional Stress

Torsional stress is fundamentally a shear stress that acts on a plane perpendicular to the axis of the applied torque. Imagine twisting a cylindrical rod; the material fibers resist this twisting action, creating internal shear stresses within the rod's cross-section. The magnitude of this stress varies depending on the distance from the center of the rod, being zero at the center and maximum at the outer surface. This distribution is critical for understanding the strength and failure modes of torsionally loaded components.

The Torsional Stress Formula

The torsional stress formula relates the shear stress (τ) at a point in a circular shaft to the applied torque (T), the radial distance (r) from the center of the shaft to that point, and the polar moment of inertia (J) of the shaft's cross-section. The formula is given by:

τ = (T r) / J

Where: τ (tau) is the torsional shear stress (typically in Pascals (Pa) or pounds per square inch (psi)).

T is the applied torque (typically in Newton-meters (N·m) or inch-pounds (in·lb)).

r is the radial distance from the center of the shaft to the point where the stress is being calculated (typically in meters (m) or inches (in)).

J is the polar moment of inertia of the shaft's cross-section (typically in m4 or in4).

Polar Moment of Inertia (J)

The polar moment of inertia represents the resistance of a cross-section to torsional deformation. Its value depends on the shape of the cross-section. For a solid circular shaft with radius R, the polar moment of inertia is:

J = (π R4) / 2

For a hollow circular shaft with outer radius Ro and inner radius Ri, the polar moment of inertia is:

J = (π (Ro4 - Ri4)) / 2

Derivation of the Torsional Stress Formula

The torsional stress formula can be derived from the assumptions of linear elasticity and the geometry of deformation. The key assumptions are:

- The material is homogeneous and isotropic.

- The material obeys Hooke's Law (stress is proportional to strain).

- Plane sections remain plane during torsion (no warping).

- The angle of twist is small.

Considering an infinitesimal element on the shaft's cross-section, the shear strain (γ) is proportional to the radial distance (r) and the angle of twist (θ) per unit length (L):

γ = r (θ/L)

According to Hooke's Law for shear, shear stress (τ) is proportional to shear strain (γ):

τ = G γ

Where G is the shear modulus of the material. Substituting the expression for γ, we get:

τ = G r (θ/L)

Now, consider the resisting torque (d T) due to the shear stress acting on the infinitesimal area (d A) of the element:

d T = r τ d A = r (G r (θ/L)) d A = (G (θ/L)) r2 d A

The total torque (T) is the integral of d T over the entire cross-sectional area:

T = ∫ d T = ∫ (G (θ/L)) r2 d A = (G (θ/L)) ∫ r2 d A

The integral ∫ r2 d A is, by definition, the polar moment of inertia (J). Therefore:

T = (G (θ/L)) J

Rearranging this equation to solve for (G (θ/L)), we get:

G (θ/L) = T/J

Substituting this back into the shear stress equation, τ = G r (θ/L), we finally arrive at:

τ = (T r) / J

Applications of Torsional Stress Analysis

Torsional stress analysis finds applications in various engineering fields. Some key examples include: Shaft Design: Designing shafts for power transmission in vehicles, machinery, and turbines. The torsional stress must be kept below the material's yield strength to prevent failure. Axle Design: Designing axles for vehicles to withstand the torsional loads imposed by the engine and drivetrain. Bolted Connections: Analyzing the torsional stress in bolts and fasteners used in structural connections. Drill Bits: Understanding the torsional stress distribution in drill bits during drilling operations. Helical Springs:Analyzing the torsional stress in helical springs subjected to axial loads.

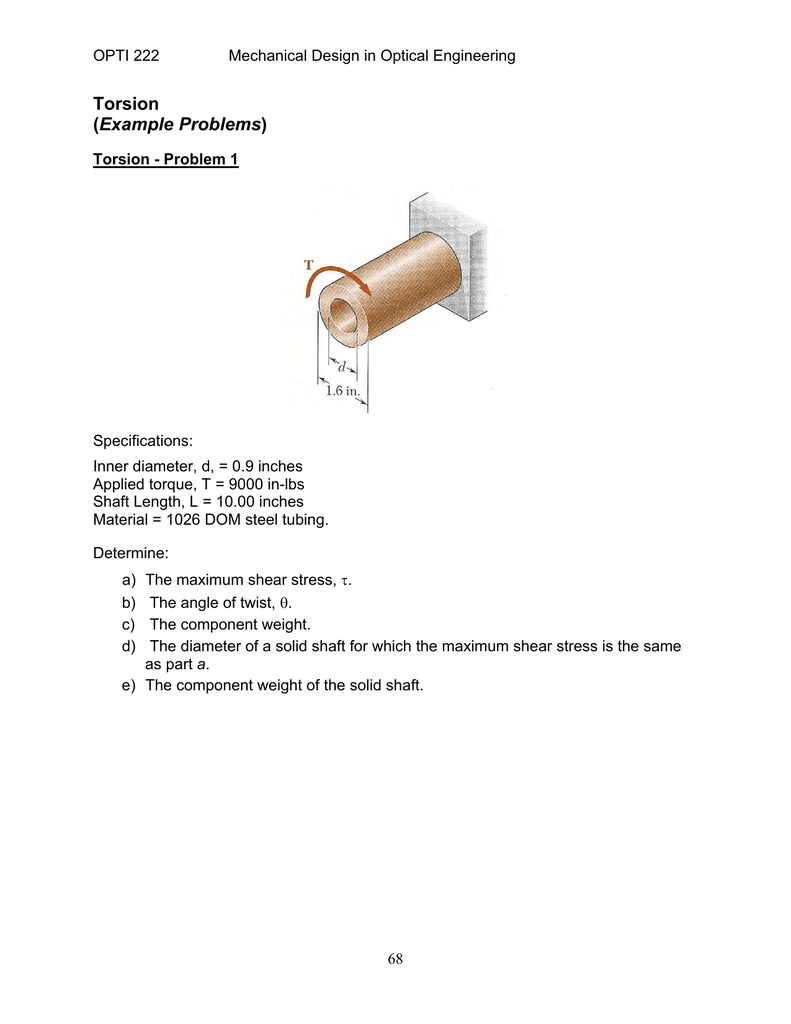

Example Problems

Let's work through some example problems to illustrate the application of the torsional stress formula.

Example 1: Solid Circular Shaft

A solid circular shaft with a diameter of 50 mm is subjected to a torque of 500 N·m. Determine the maximum shear stress in the shaft.

Solution

0.025 m

2.Calculate the polar moment of inertia (J): J = (π R4) / 2 = (π (0.025 m)4) / 2 ≈

6.136 x 10-8 m4

3.Apply the torsional stress formula: The maximum shear stress occurs at the outer surface of the shaft (r = R). τmax = (T R) / J = (500 N·m

0.025 m) / (6.136 x 10-8 m4) ≈

203.7 x 106 Pa =

203.7 MPa

Therefore, the maximum shear stress in the shaft is approximately 203.7 MPa.

Example 2: Hollow Circular Shaft

A hollow circular shaft has an outer diameter of 100 mm and an inner diameter of 60 mm. It is subjected to a torque of 10 k N·m. Determine the shear stress at the outer and inner surfaces of the shaft.

Solution

1.Calculate the outer radius (Ro) and inner radius (Ri): Ro = Outer Diameter / 2 = 100 mm / 2 = 50 mm =

0.05 m, Ri = Inner Diameter / 2 = 60 mm / 2 = 30 mm =

0.03 m

2.Calculate the polar moment of inertia (J): J = (π (Ro4 - Ri4)) / 2 = (π ((0.05 m)4 - (0.03 m)4)) / 2 ≈

8.545 x 10-7 m4

3.Calculate the shear stress at the outer surface (τo): τo = (T Ro) / J = (10,000 N·m

0.05 m) / (8.545 x 10-7 m4) ≈

585.1 x 106 Pa =

585.1 MPa

4.Calculate the shear stress at the inner surface (τi): τi = (T Ri) / J = (10,000 N·m

0.03 m) / (8.545 x 10-7 m4) ≈

351.1 x 106 Pa =

351.1 MPa

Therefore, the shear stress at the outer surface is approximately 585.1 MPa, and the shear stress at the inner surface is approximately

351.1 MPa.

Common Pitfalls and Misconceptions

Assuming Uniform Stress Distribution: A common mistake is to assume that the shear stress is uniformly distributed across the shaft's cross-section. However, as the formula shows, the stress is proportional to the radial distance. Incorrect Polar Moment of Inertia: Using the wrong formula for the polar moment of inertia can lead to significant errors. Always use the correct formula based on the cross-sectional shape (solid, hollow, etc.). Units: Ensure that all units are consistent before applying the formula. Mixing units (e.g., using meters for radius and millimeters for diameter) will result in incorrect stress calculations. Stress Concentrations: The torsional stress formula assumes a uniform shaft geometry. Stress concentrations can occur at sharp corners, holes, or changes in diameter, which can significantly increase the stress levels. These stress concentrations need to be accounted for in a more detailed analysis, often involving Finite Element Analysis (FEA). Beyond Elastic Limit:The torsional stress formula is based on the assumption of linear elasticity. If the applied torque is high enough to cause plastic deformation, the formula is no longer valid.

Advanced Considerations

For more complex scenarios, such as non-circular cross-sections or shafts with varying diameters, more advanced analysis techniques are required. These include: Finite Element Analysis (FEA): FEA can be used to simulate the stress distribution in complex geometries under torsional loading. Experimental Stress Analysis: Techniques like strain gauging can be used to measure the actual stress distribution in a component under torsional load. Torsion of Non-Circular Sections: For non-circular sections, the analysis becomes more complex as the assumption that plane sections remain plane is no longer valid. Specialized formulas and techniques are required to analyze these cases. Combined Loading: In many real-world applications, shafts are subjected to combined loading, including torsion, bending, and axial loads. The combined stresses must be considered to ensure the component's safety.

Conclusion

Understanding the torsional stress formula is fundamental to analyzing and designing components subjected to twisting forces. By grasping the underlying principles, the formula's derivation, and its applications, engineers can confidently address various design challenges involving torsional loads. Remember to consider the limitations of the formula and to account for factors such as stress concentrations and combined loading when necessary.